When it comes to woodworking projects, choosing the right adhesive is crucial for ensuring strong and durable bonds. Among the various types of glue available, cold glue and wood glue are two popular options. Understanding the differences between these adhesives can help you select the best one for your specific woodworking needs.

What is Cold Glue?

Cold glue is a type of adhesive that is applied at room temperature, making it easy to use without the need for heating equipment. This glue is typically water-based and is known for its versatility in bonding various materials, including wood, paper, cardboard, and some plastics. Cold glue is particularly popular in industries where quick drying times and strong adhesion are essential, such as in packaging and assembly lines.

What is Wood Glue?

Wood glue, specifically designed for woodworking applications, is formulated to create strong bonds between wood surfaces. It often contains polyvinyl acetate (PVA) or polyurethane, providing excellent adhesion and durability. Wood glue is ideal for various woodworking tasks, including furniture assembly, cabinetry, and repairs. It typically dries clear and can be sanded or painted over, making it suitable for finished wood projects.

Key Differences Between Cold Glue and Wood Glue

Composition:

Cold glue is usually water-based and can bond a variety of materials.

Wood glue often contains PVA or polyurethane, specifically formulated for wood.

Application:

Cold glue can be used on multiple substrates, making it versatile for various applications.

Wood glue is tailored for wood surfaces, offering superior adhesion specifically for woodworking tasks.

Drying Time:

Cold glue generally dries quickly, which is advantageous in fast-paced production environments.

Wood glue may take longer to set, depending on the type, but it provides a strong long-term bond once cured.

Strength:

Cold glue can create strong bonds but may not match the adhesion strength of specialized wood glues for woodworking projects.

Wood glue is designed to provide the strongest bond for wood joints, making it the preferred choice for carpenters and woodworkers.

Uses:

Cold glue is ideal for applications like packaging, bookbinding, and general assembly tasks.

Wood glue is best suited for furniture making, cabinetry, and any project where wood joints need to be securely bonded.

Conclusion

In summary, while both cold glue and wood glue have their unique advantages, the choice between them largely depends on the specific requirements of your woodworking project. Cold glue offers versatility and quick setting times, making it suitable for various materials, while wood glue provides the strongest bond for woodworking applications.

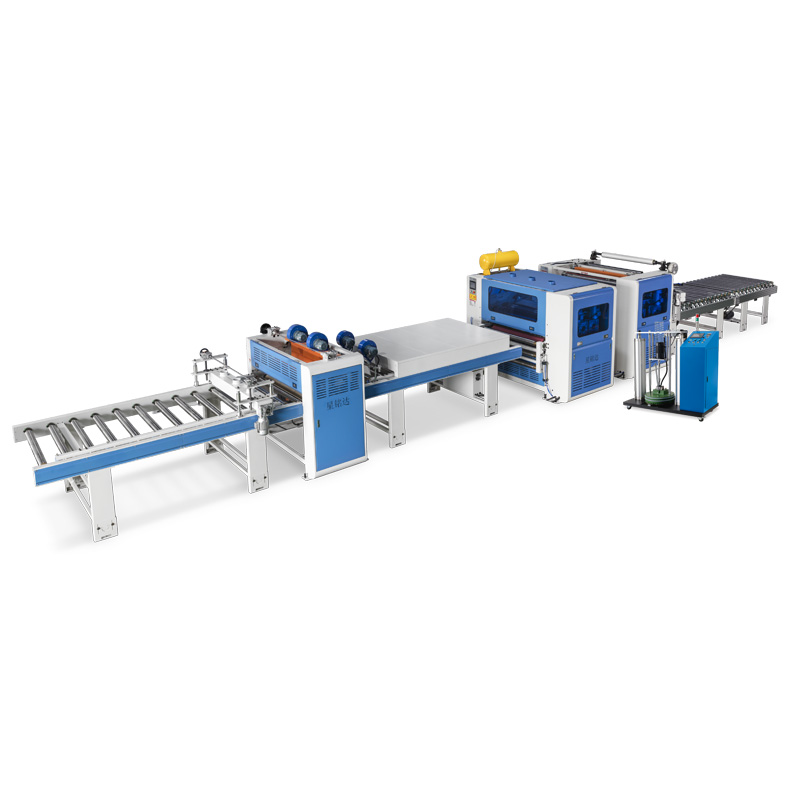

For those in the woodworking industry looking to enhance their production efficiency, investing in a Cold Glue Wrapping Machine can streamline the packaging process. Foshan Xing Mingda Automatic Equipment Machinery Co., Ltd. specializes in high-quality woodworking machinery, including cold glue wrapping machines that ensure precision and reliability in your projects. Explore their offerings to elevate your woodworking capabilities today!